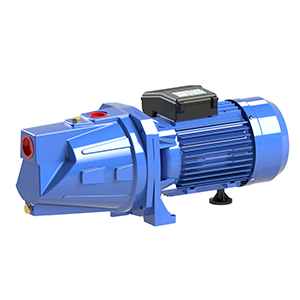

Self-Priming Jet Pumps

This type of pumps, which have a wide range of use in domestic, are designed in accordance with this type of water pump booster systems, which are produced in different types between 0.85 – 2.2 HP and suitable for different usage purposes.

This type of pump can suction from a depth of 9 meters.

This type of pumps, also known as jet water pump, are preferred products due to their easy installation. Turkey manufacturer of jet water pump.

SMJ85 - SMJK100

SMJ100

| MOTOR | POMPA | ||||||||||||||||

| TİP | KW | HP | V | Hz | A | d/d | Kapasitör | Çıkış | W | L | H | KG | 0.5 | 1 | 2 | 3 | |

| SMJ85 | 0.65 | 0.85 | 220 | 50 | 4.6 | 2900 | 20 | 450 | 1″ | 180 | 368 | 211 | 12.5 | 42 | 36 | 31 | 15 |

| SMJT85 | 0.65 | 0.85 | 380 | 50 | 1.7 | 2900 | 20 | 450 | 1″ | 180 | 368 | 211 | 12.5 | 42 | 36 | 31 | 15 |

| SMJK100 | 0.75 | 1 | 220 | 50 | 4.7 | 2900 | 20 | 450 | 1″ | 180 | 368 | 211 | 12.5 | 41 | 41 | 34 | 22 |

| SMJKT100 | 0.75 | 1 | 380 | 50 | 2.2 | 2900 | 20 | 450 | 1″ | 180 | 368 | 211 | 12.5 | 41 | 41 | 34 | 22 |

| SMJ100 | 0.75 | 1 | 220 | 50 | 5.2 | 2900 | 20 | 450 | 1″ | 180 | 407 | 211 | 15 | 48 | 45 | 37 | 27 |

| SMJT100 | 0.75 | 1 | 380 | 50 | 2.2 | 2900 | 20 | 450 | 1″ | 180 | 407 | 211 | 15 | 48 | 45 | 37 | 27 |

DESCRIPTION

Self-Priming jet pump work in silence, self-priming jet pumps. This type jet pumps manufactured at frequencies of 50 Hz and 60 Hz.

FIELDS OF USAGE

This type jet pumps are irrigation in gardens of small diameter up to a maximum of 52 m height, suctioning from a depth of 7-9 m; because of technological design, silence and no need to maintenance, it is used in the supply of clean water for water booster not exceed 4 times in buildings, villa and summer.

| Pump Body | GG25 Döküm |

| Wheel | Noryl |

| Shaft | Aısı 304 Inox |

| Flow (max) | 3.5 m3 /saat |

| Discharge head | 52 m |

| Liquid Discharge Temperature | 0-45°C |

| Protection Class | IP 54 |

| Insulation | CI.F |

| Cable Length | 10 m |

| Mechanical Seal | Seramik/Karbon |

| Pump Withstand Pressure (Pmax) | 8 bar |

*Monophase models have thermal protection against overloads.

SMJ150

SMJ220

| MOTOR | POMPA | |||||||||||||||||

| TİP | KW | HP | V | Hz | A | d/d | Kapasitör | Çıkış | W | L | H | KG | 1 | 2 | 3 | 4 | 5 | |

| SMJ150 | 1.1 | 1.5 | 220 | 50 | 5.8 | 2900 | 25 | 450 | 1″ | 180 | 407 | 211 | 15 | 51 | 42 | 25 | 5 | – |

| SMJT150 | 1.1 | 1.5 | 380 | 50 | 2.6 | 2900 | 25 | 450 | 1″ | 180 | 407 | 211 | 15 | 51 | 42 | 25 | 5 | – |

| SMJ220 | 1.6 | 2.2 | 220 | 50 | 8.8 | 2900 | 45 | 450 | 1¼ | 207 | 548 | 230 | 30.5 | 67 | 60 | 53 | 47 | 38 |

| SMJT220 | 1.6 | 2.2 | 380 | 50 | 3.5 | 2900 | 45 | 450 | 1¼ | 207 | 548 | 230 | 30.5 | 67 | 60 | 53 | 47 | 38 |

DESCRIPTION

Jet pumps work in silence, self-priming jet pumps. This type jet pumps manufactured at frequencies of 50 Hz and 60 Hz. Turkey manufacturer of jet water pump.

FIELDS OF USAGE

This type jet pumps pressurized water up to a maximum height of 74 m, sucked from a depth of 9 m, it is used to supply clean water for booster in buildings up to 10 floors and 20 apartments. Turkey manufacturer of jet water pump.

| Pump Body | GG25 Döküm |

| Wheel | Noryl |

| Shaft | Aısı 304 Inox |

| Flow (max) | 6 m3 /saat |

| Discharge head | 74 m |

| Liquid Discharge Temperature | 0-45°C |

| Protection Class | IP 54 |

| Insulation | CI.F |

| Cable Length | Seramik/Karbon |

| Mechanical Seal | 10 bar |

| Pump Withstand Pressure (Pmax) |

*Monophase models have thermal protection against overloads.

Self Priming Jet Pumps

Jet pumps are centrifugal pumps formed by adding an additional jet ejector to a structure with one or more propellers and diffusers. The most important feature of the jet water pump is that, due to the injector, some of the pressurized water in the outlet line is given to the suction line and suction from deeper wells. Jet pumps manufactured by turkish jet pump producers are pumps that are generally mounted on the ground and allow the water to be evacuated through a suction pipe. Jet pumps are widely used in areas where groundwater is abundant.

Regarding the selection of jet pumps , The most important parameter in the separation of this type of centrifugal pumps is the depth of the water level. Suction Jet pumps have a wide range of use in domestic use. We have different types of suction jet pumps between 0.85 – 2.2 HP, suitable for different purposes of use. Self-Priming Jet water pump produced by turkish jet pump manufacturers can suction from a depth of 9 meters.

The jet water pump, also known as the jet water dynamo is the preferred product because it is easy to install. In the jet water pump installation, bottom valves are used as deep suction will be made.

Self-Priming Jet Centrifugal Pumps are manufactured with a power between 0.85 – 2.2 HP and are suitable for use in many different areas with TSE certificate. Pumps are designed and manufactured in accordance with TS EN ISO 9908 standard. In the electric motor windings, F insulation class cables are used in accordance with TS 60085:2011. User and motor safety are prioritized by using a 2-pole asynchronous motor with IP 54 protection class in accordance with TS 3033 EN 60529. If we talk to the working principle of the Jet Water Pump, in these pumps consisting of a vane impeller in a body, the liquid enters the pump through a suction pipe.

The path of the jet water pump liquid is as follows. Regarding the installation of jet pumps , Due to the vacuum created on the suction side of the impeller, the liquid enters between the blades of the impeller. The fluid passing between the impeller blades gains a great tangential velocity with the rotational movements of the impeller. Between the impeller blades and the channels bounded by the front and rear profiles of the impeller, the liquid is pushed towards the exit side of the impeller by the centrifugal force that occurs during the rotational movement. The movement created in this way ensures the continuous flow of liquid and suction from the suction side of the pump. The kinetic energy contained in the liquid leaving the impeller blades with a great tangential velocity is converted into a pressure force in the volute cavity between the fixed diffuser blades. The highest pressure is achieved with a given rotational speed.