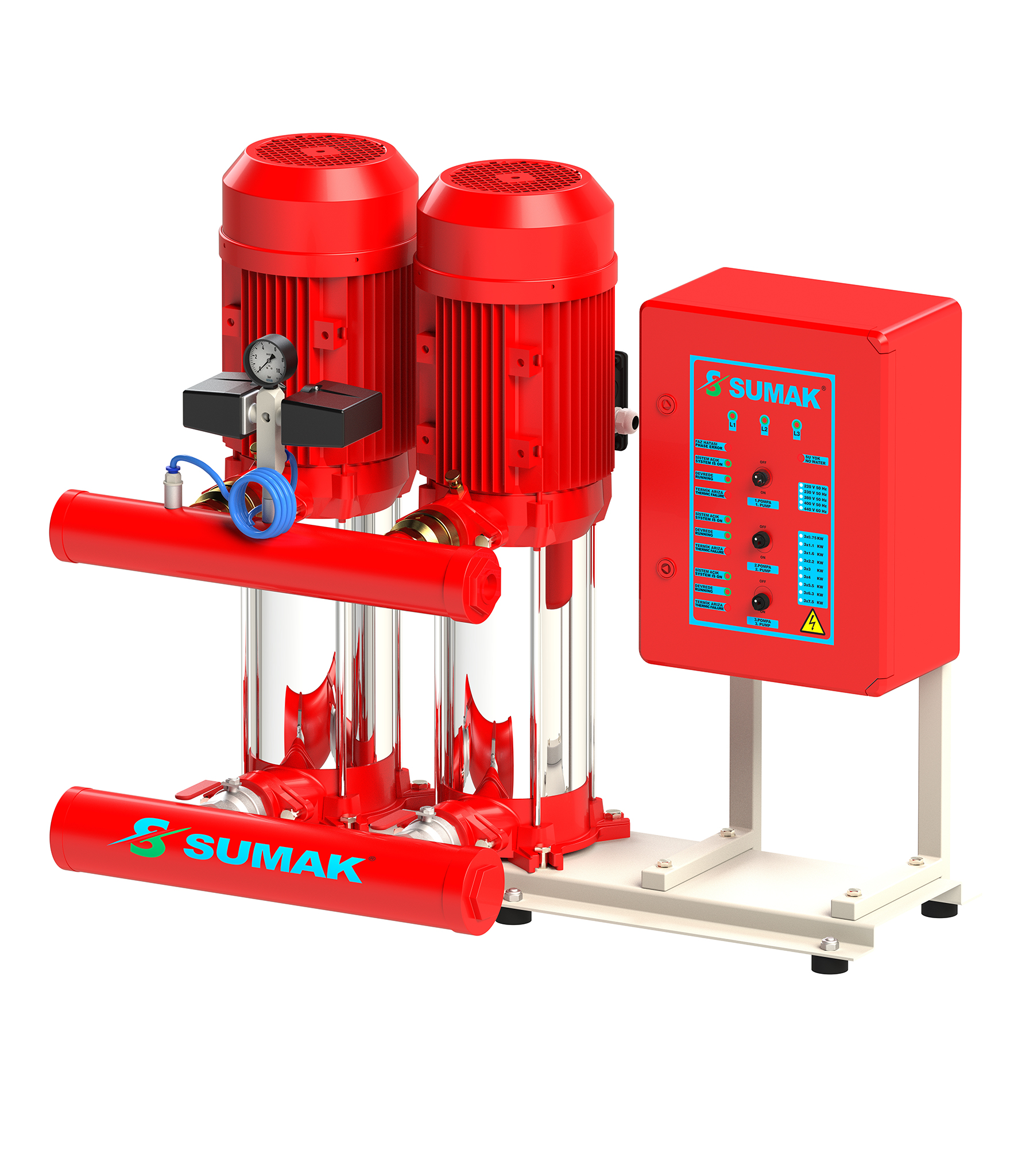

Fire Fighting Systems

Sumak Pump is one of the leaders of fire pumps systems manufacturers in Turkey. Fire pumps systems are exported to 33 countries.We are conscious of the importance of the quality and compliance with the standards about producing of firefighting systems, very well. And we produce our fire pumps systems with this sense of responsibility. We continue to be preferred by you as a fire pumps manufacturer.

Fire pumps are produced in compliance with TSE and NFPA20 standards in the range of 10 m³/h and 450 m³/h and can be produced as Electrical, Electrical and Diesel, Diesel + jockey systems.

These types of fire booster sets are designed with electrical pumps selected according to power, flow pressure values indicated in the project, suitable to NFPA20 standards (the standards necessary for installation of pumps), and used in military facilities, hotels, hospitals, business and shopping centers, factories, public housings, warehouses, ships, school and social service buildings.

By clicking the link of photo, you can reach the technical specifications of fire pumps to find the suitable pumps according to the application areas and your projects.

The startups of the fire booster sets are performed by our technical services in 81 cities. Manufacturer of fire fighting pumps Turkey.

FIRE PUMP / FIRE EXTINGUISHING PUMPS

Fire pumps are water pumps working with electricity or fuel, produced for use in the fire system by increasing water pressures. Manufacturer of fire fighting pumps Turkey. Fire Pumps produced by Turkish Fire pump manufacturers , with the help of high pressure, deliver the water they absorb from a certain water reservoir to remote fire cabinets and sprinklers. Because of the expansion tanks connected to the Fire Boosters, they already hold pressurized water. Fire Booster manufactured by Turkish fire booster producers is a fire extinguishing system that is formed by integrating one or more pumps from pumps with a minimum 8 bar pressure with flow rates between 12 m³/h – 300 m³/h using a common chassis and collectors.

What is a fire pump ;

Fire Pumps: These are fire pumps that provide pressurized water in water extinguishing systems and are expressed with nominal flow rate and nominal pressure value. They are fire extinguishing pumps that are used in buildings, industrial facilities, in every area that comes to mind when it comes to service and production, in possible fire situations that can cause great damage to life and property caused by people or the environment. Of course, taking precautions against every situation that may cause a fire, not after the fire has broken out, is of course a priority. However, due to certain conditions, unconscious personnel, human or material problems, a fire may occur despite all precautions. One of the measures taken in such cases is fire extinguishing systems.

How does a fire pump work;

Let’s summarize the working principles of the fire pump with a few items;

The fire pump produced by turkish fire pump manufacturers should be selected to meet the pressure and flow required during a fire; this is one of the critical points in fire pump selection.

Fire pump systems consist of main and backup pumps. In this sense, it is an important detail to project the main fire pumps as redundant, because a B plan is always required in case of possible risks.

Fire pumps used in fire extinguishing systems are controlled by a control panel. A separate control panel for each fire pump These panels are positioned in accordance with the relevant standards and regulations.

Electric motor driven or diesel fire pumps produced by Turkish fire water pump system manufacturers can be used in fire extinguishing systems. If the system pressure in the fire extinguishing installation falls below the value set by the pressure switch of the fire pump, the fire pump is activated automatically. Signal information comes from the pressure switch and this information is transmitted to the control panel. The fire pump manufactured by turkish fire system producers is activated according to the incoming pressure information and is deactivated when necessary with the stop switch on the control panel. Since occupational safety and protection of human health are essential in fire pump systems, the manufacture and combination of products is made in accordance with the standards set by the National Fire Protection Association. This standard is called NFPA 20 for fire pumps and is the most adopted fire extinguishing standard in the world. Automatic sprinklers, fire cabinets for the building, external hydrant systems are designed according to NFPA 20 Standards. According to this standard, fire pump and pump systems should consist of the following features.

- If the flow at the pump operating point increases by 150%, the operating pressure should not exceed a minimum of 65%.

- Pump closed valve pressure should not exceed 140% of the working pressure.

- Pump body should be cast iron (GG25-GG40).

- Parts that come into contact with water must be made of water-resistant, non-oxidizing material. Impeller: Bronze (CuSn10), Shaft: AISI 304

- Soft packing should be used as a sealing element in pumps and should be arranged in at least 5 rows.

- “Safety Valve” should be used in fire extinguishing pump produced by Turkish fire pump manufacturers systems to prevent high pressure from damaging system equipment.

- Fire pump extinguishing systems should be in the form of 1 main + 1 spare + Jockey pump.

- Where there is no generator, the backup pump must be diesel engine driven.

- Bearings should be selected according to 5000 hours life calculation.

- In the facilities where there is enough powerful generator, the backup pump can be electric motor driven.

- Jockey pump operating pressure must be at least 0.7 bar above the fire pump pressure.

- Losses must be calculated with a minimum pressure of 8 bar at the furthest point in the fire system and the pump pressure must be determined.

- NFPA 20 suitable jockey pump selection is 1% of the desired flow rate or 3-3.5 m3/h capacity per hour.

Vertical Shaft Stage Fire Boosters

Vertical Shaft Multistage Pumps They are products that facilitate use in places where there is a horizontal space problem, they are used for fire booster purposes, The pumps are designed with more than one impeller and stage on a vertical shaft. Although the material of the pump impeller is usually noryl, they can also be manufactured as stainless and cast. Such pumps can also be used as fire pumps in small businesses. The asynchronous motor driving the pump is designed to be on top of the pump, the pump is usually connected to the system with an easy mounting apparatus called a glen (flange) and can be easily disassembled in case of maintenance. Fire pumps produced by Turkish vertical shaft fire pump manufacturers have a few extra equipment compared to other boosters, one of which is the weekly test system. Since fire pumps do not operate unless there is any leakage or use in the installation, they can operate the pump for at least 10 seconds every week against mechanical interlocks. Vertical Shaft Stage Fire Boosters, with a flow rate of 10 m³/h to 34 m³/h, are suitable for use in industries, hospitals, residential units, hotels, mass housing, gas stations, holiday villages, shopping centers, social facilities, fire systems, and for pressurized water need.

Horizontal Stage Fire Extinguishing Systems

Horizontal Stage Fire Pump can be used directly from the well by connecting directly to the fire installation by suctioning from a certain depth, as well as can make suction on the underground water tank, this type of sumak pump product booster, which also has the feature of a silent working booster, has a very wide range of use. Horizontal Stage Fire Pump produced by Turkish horizontal stage fire pump manufacturers are produced from Sumak SMKT550, SMKT750, SMKT550/2, SMKT 750/2 models with flow rates between 12 m³/h and 26 m³/h, these pumps are double-stage pumps, they consist of two impellers and a diffuser. In this way, it provides suction from approximately 4 meters. This type of suction booster system, which is ideal for a comfortable booster system by suctioning up to a maximum of 4 m, can be easily maintained and repaired. Horizontal Stage Fire Pump double stage booster systems, which give regular and continuous water according to the need at determined pressures, are suitable for use in schools, hospitals, workplaces, mass housing, hotels, etc. When two or more pumps are used in the Horizontal Stage Fire Pump pumps, the collector is not used in the suction line. The reason is that since suction is made from the negative elevation with the collector, it has been determined that the pumps have difficulty in suction and damage the impellers and even the pump, so each pump is provided with self-priming.

End Suction Fire Suppression Systems

It is an end-suction fire extinguisher created from Volute Pumps. Pumps generally consist of a common suction collector and a common discharge collector on a chassis. Since it has a collector, it is not suitable for suction from minus elevation. End Suction Fire Extinguishing Systems produced by Turkish end suction fire water pump manufacturers consist of a main and a spare and jockey pump, the backup pump is produced electrically in places with generator feeding, and the backup pump is produced from a diesel driven volute pump in places where there is no generator. Fire extinguishing boosters with a flow rate between 12 m³/h and 300 m³/h are used in military facilities, hotels, hospitals, business and shopping centers, factories, mass housing, warehouses, ships, schools and social service buildings.

Double Suction Fire Suppression Systems

Double suction split case pumps, also known as Split Case, are centrifugal pumps with impeller model that sucks from both sides. The suction and discharge ports of the pump are in opposite directions. Balancing is provided by bearings placed on the shaft in a symmetrical position. Maintenance is easy as the upper part of the body can be easily dismantled. because of their symmetrical structure, they work in a very balanced way. The double suction impellers used give better NPSH performance, while the axial forces are kept at a very low level. They can reach higher flow rates than end-suction pumps and have a lower risk of cavitation. It can be used in systems where high flow rate is required. Split casing centrifugal pumps produced by Turkish split case fire pump manufacturers are primarily preferred to fire suppression systems. Split casing, Double Suction pumps can be produced with Electric and Diesel Engine options in application projects with values of 60 m³/h – 300 m³/h.

Turkey fire pump manufacturer / fire pump manufacturer Turkey / quality fire pump manufacturer / fire pumps / fire pump selection / fire pump sets / fire pump set / fire fighting systems / fire fighting pumps /